MICROMACHINES AND NANOTECHNOLOGY: The Amazing New World of the Ultrasmall - 3. Gearing Down

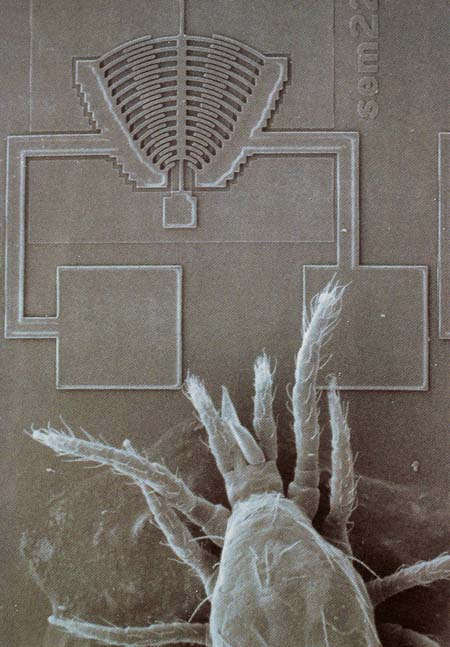

Figure 1. A tiny mite, barely visible to the unaided eye, moves toward a micromechanical device.

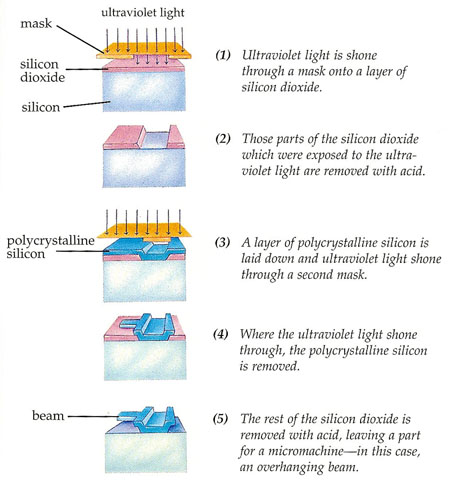

Figure 2. How to make a part for a micromachine.

Figure 3. Micromechanical Velcro.

Researchers have found out how to make electronic components incredibly small. Now they are also learning how to create microscopic versions of machines like gears, pumps, and motors. These miniature moving gadgets are known as micromachines or micromechanical devices (see Figure 1).

Many people have heard about microchips and how important they are in all sorts of ways. By comparison, not so much has been said in the media about micromachines. One of the reasons for this lack of attention is that micromachines are a lot harder to make and so scientists are still working to perfect them. Over the next few years, however, micromachines will become more and more common in everyday life. Eventually, they may just as important a part in the running of our modern world as microchips do today.

Microscopic Motors

Micromachines took a giant step forward in 1988 when a team for the University of California at Berkeley demon started a working electric motor that could be seen only with the help of a microscope. This motor had a main spinning part, or rotor, that measuring just 60 micrometers, or millionths of a meter, across. If this rotor had been made ten times bigger, it would still have been only as wide as a pin.

Since then, even smaller micromotors have been built. Teams of scientists all over the world are studying how to make these motors work more efficiently and produce more turning force, r torque, so that they will be able to do useful jobs.

One of the biggest problems with micromotors is friction, the force that acts when surfaces rub against one another. Friction is what stops your bicycle when you put on the brakes. We depend on friction to prevent us from skidding every time we walk. But inside a machine that is supposed to move freely and easily, friction is a nuisance.

With an ordinary-size electric motor, such as the one in a washing machine, the frictional forces usually add up to less than a hundredth of the torque that the motor produces. In micromotors, however, the friction can be as big as the torque. When this happens, the motor is stopped from moving.

The first micromotors tended to lock up after just a few thousand spins. Scientists working on these very small devices realized that they would have to pay special attention to designing bearings that cut down friction as much as possible. Their efforts have been very successful. The latest micromotors are still hampered by friction, but the amount of friction can be reduced to less than 10 percent of the torque. As a result, micromotors can now run for days on end at low speeds or in short bursts at up to 15,000 revolutions per minute.

Making a Micromachine

Using methods borrowed from siicon-chip technology, researchers started making micromachines in the 1970s. But they quickly realized that these methods would have to be adapted in various new ways, because microelectronic components are more or less flat, whereas micromechanical ones are three-dimensional. Micromachines have length, width, and height.

To construct a micromachine, scientists make a multilayer silicon sandwich. On the bottom is a single crystal of silicon. Above this is a layer of silicon dioxide. Next comes another layer of silicon, called polycrystalline silicon, or POLYSILICON, because it is made of lots of little jumbled-up crystals. On top of this is a second layer of silicon dioxide, followed by a second layer of polysilicon.

The moving parts for a micromachine are made by masking and dissolving away specific regions of the second (top) polysilicon layer. Acid is used to remove the unwanted portions of the silicon dioxide layer below, leaving the moving parts free to spin or pivot. The underlying polysilicon layer provides the secure base upon which the micromachine motors and levers can move.

Alternatives to Silicon

In some ways silicon is a good building material for micromachines. It is almost twice as hard as iron and more difficult to stretch than steel. Silicon's biggest drawback is that it is brittle – it can crack or shatter quite easily. Even little bits of silicon that break off inside a micromachine can act as grit that stops the device from working.

In the early 1980s a group of scientists at the Karlsruhe Nuclear Research Center in Germany began developing a new method for making micromachines. This method is known by the initials – LIGA. Using LIGA, researchers can build micromachines from nickel and other metals that are much less brittle than silicon.

Instead of the ultraviolet rays used in microchip technology, LIGA uses X-rays. The X-rays are shone through a mask – a stencil of the machine being made – onto a layer of polymer. Then a develop is used to dissolve the polymer where the X-rays have penetrated it. Up to this point, LIGA follows steps similar to those involved in making silicon microchips.

Next, however, an electrical process fills the gaps in the polymer with nickel or a metal like nickel. When this has been done, the rest of the polymer coating is dissolved away.

The nickel shape that is left behind can be used either directly or as part of a micromachine or as a master mold from which to make copies. To produce copies, technicians place a layer called a casting plate over the nickel. Through tiny holes in this casting plate, hot liquid plastic is injected. When the plastic has cooled and hardened, it is lifted off and used as a mold for making duplicates of the original nickel structure.

Better Micromachines

To make a micromotor with spinning parts that a finer than a human hair is an amazing achievement. But can these tiny devices do any useful jobs? One of the problems with micromotors is that they produce very little torque. Once the friction between their moving parts has been overcome, they can often barely keep their own rotors spinning around, much less help turn any larger devices to which they might be attached.

One way to increase the power of a micromotor is to build it less like a pancake, because the size of a motor's torque increases with the height of its spinning parts. The methods use for manufacturing silicon micromachines are not suited to producing structures higher than about 10 micrometers. However, if nickel and the LIGA process are used, this height limit can be overcome.

Researchers in Germany made a nickel devices that was only 5 micrometers wide, but 300 micrometers high. At the University of Wisconsin, another team of scientists made toothed nickel gears, 50 to 200 micrometers across and 200 to 300 micrometers high. These toothed wheels were linked together to form gear trains. Such gear trans could eventually be used to transmit the motion of a micromotor to other pieces of equipment nearby.

| Micro Velcro

Researchers at Carnegie-Mellon University in Pittsburgh have shown that microchip manufacturing methods can be used to create what they call micromechanical Velcro (see Figure 3). First they grow a silicon dioxide layer on a silicon base. Then they repeatedly mask chosen areas and remove the unwanted parts with acid. The process produces silicon dioxide arrowheads, or hooks, on silicon pedestals. Each structure is no more than 18 micrometers wide, and 200,000 of them can be packed onto a square centimeter.

The tiny arrowheads will pierce human flesh and then hold fast because of their barbed ends. The Pittsburgh team believes the arrowheads could be used to rejoin severed blood vessels and to close wounds in place of stitches. But unlike everyday Velcro, the microscopic version does not pull apart easily. Instead, the hooks tend to break off as they are separated. |

Swimming Bacteria and Medicine

In Japan a team of scientists investigated another kind of micromechanical device that could eventually be used in medicine. These scientists looked at ways to propel machines inside a patient's body to deliver lifesaving drugs. Ordinary micromotors might not be able to move in blood, which is quite a thick liquid. So, to solve this problem, the Japanese scientists looked at the possibility of copying the tiny whiplike structures that some kinds of bacteria use to move around. These structures, which are only 30-billionths of a meter in diameter, are called flagella.

It has been known for some time that parts of a flagellum work like an ordinary electric motor. Close to where it joins the main body of the bacterium, the flagellum has a rotor that spins around inside a fixed ring.

The Japanese scientists want to discover the exact arrangement of chemicals that help such a tiny structure to work so effectively. With this knowledge, they hope to make a computer model of the flagellum and then try to figure out how to produce an artificial version. Such an advanced micromachine probably lies many yeas in the future, however.